Space exploration with Pfaff-silberblau worm gear screw jacks from Columbus McKinnon Engineered Products

By | May 22, 2017

In the South African Karoo semi-desert, astronomers working on the MeerKAT project are using 64 radio telescopes from the German manufacturer Vertex Antennentechnik to explore space. The elevation movement of the antennas is effected using the innovative technology from Columbus McKinnon Engineered Products, Kissing. To meet the customer's exacting requirements, the engineers had to quickly devise a special drive system. In a record time of just three months from the initial request everything was accomplished from the concept design, development, prototype for testing of test scenarios through to the release for series production. The TQS 200 is a new Pfaff-silberblau torque screw jack, which now allows the inclination of the radio telescopes measuring 13.50 m in diameter to be adjusted free from backlash and to the precise millimetre. Altogether, the individual Vertex antennas combine to form what is known as a square kilometre array (SKA) – which is today regarded as the largest radio telescope in the southern hemisphere. On the basis of the radio waves received from space, the first structures of the universe are to be explored in a bid to further the search for extraterrestrial life.

Back-lash free over the entire stroke

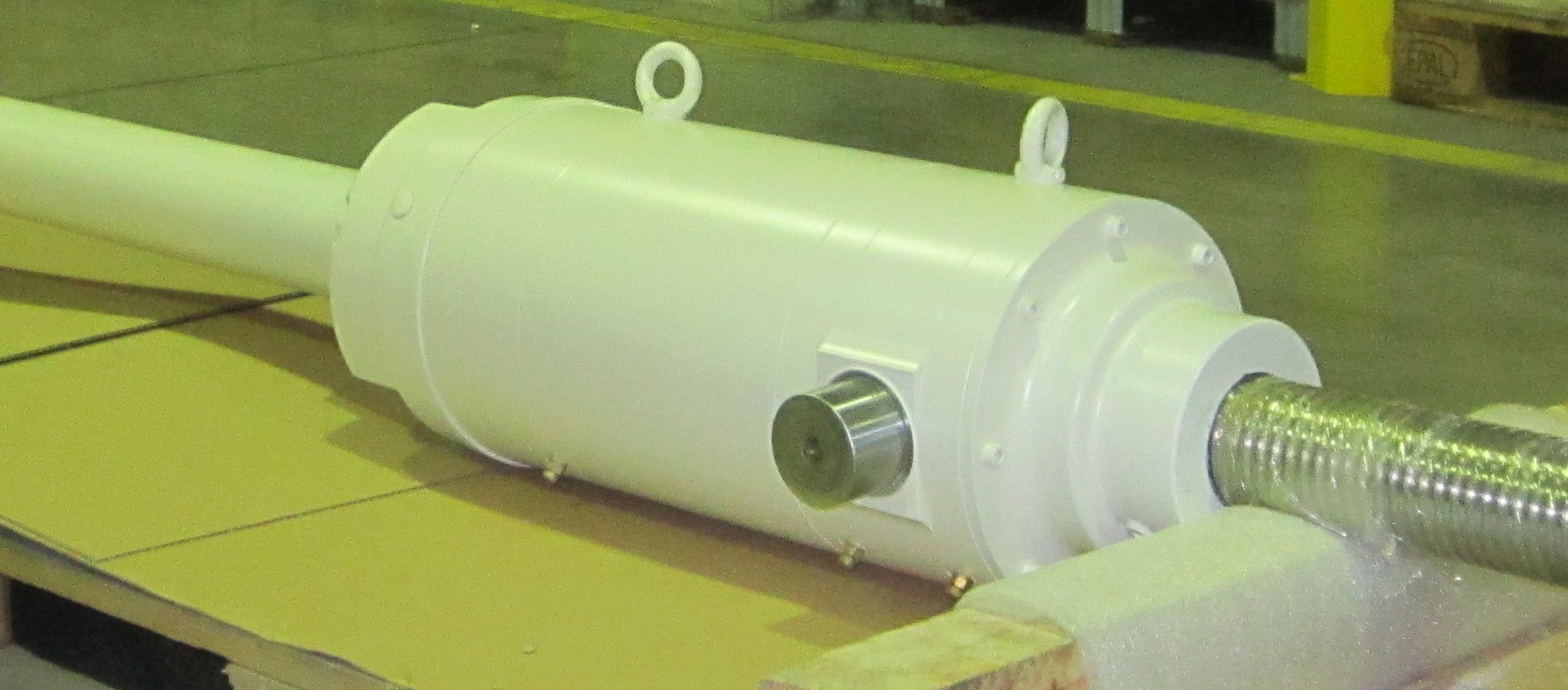

The inclination of each telescope is adjusted to the precise millimetre by the TQS 200 torque screw jack from Pfaff-silberblau. It consists of a prestressed special ball screw, which is actuated free from backlash by a torque motor with a nominal torque of over 100 Nm. The challenges posed by this special development resulted from having to ensure the necessary high rigidity, minimal friction losses and back-lash free adjustment with the best possible efficiency. For instance, it was necessary for the customer to fully ensure prescribed parameters for all the screw jacks, e.g. a low idling torque of less than 60 Nm at maximum speed and to document these accordingly.

For a stroke of 750 mm and a lifting speed in an adjustment range of 0.01 to 42 mm/s, the drive moves a load up to 25 kN free from backlash and more precisely than 5 micrometres. For this purpose, a special binary encoder is integrated free from backlash directly on the motor shaft. An emergency brake is connected with positive engagement with all the torque transferring parts. Its braking torque of 310 Nm ensures that the non-self-locking drive is held reliably and safely in all the requested positions.

Resistant in harsh environment

The highly sensitive telescopes are directly exposed to the harsh local weather conditions of this semi-desert region. For this reason, Columbus McKinnon Engineered Products has protected the TQS 200 screw jack with a multi-layer paintwork (C5-M), capable of withstanding the coastal and offshore atmosphere with its high salt content. This means the screw jack is optimally designed for the demanding environmental conditions, being resistant to both condensation and air contamination over a period of decades without impairments. All the transitions, interfaces, cable inlets and outlets as well as the terminal box have been protected by means of a special sealing concept and guarantee the electromagnetic compatibility (EMC).

The application and deployment site in the desert call for maintenance-free operation, which can be assured by using a sophisticated roller bearing mounting and the special lubricating grease developed specifically for this application. The requirement for a 30 year service life was exceptionally demanding in this new development. Consequently, all the components and assemblies in the power transmission were designed to ensure long-life fatigue strength. The high durability of the TQS 200 has now also been proven in an endurance test in a Vertex test set-up.

Elaborate testing procedure for proving the rigidity

To prove that all the specifications had been met, a complete test procedure was developed from scratch and documented in a process sequence specially devised for this. To this end, Columbus McKinnon Engineered Products provided the state materials testing institute for mechanical engineering of the Technical University of Munich with prototypes, which were used to prove the rigidity, i.e. the linear deformation under tensile and compressive loading. This involved exposing worm gear screw jack systems with overall lengths of 1000 mm and 1270 mm to a 10 kN load. Multiple load cycles were examined in the range from 0 to 100 kN for a load change of 1000 N per second. The measurements also comprised a brake test. This entailed supplying current to the drive motor with the brake on until a 310 Nm torque was reached.

Further information on worm gear screw jacks of the Pfaff-silberblau brand from Columbus McKinnon Engineered Products is available online at http://www.pfaff-silberblau.com/de-Komponenten-Produkteen-Components-Products/de-Hubelementeen-Screw-Jacks-.html.

Further information on the MeerKAT project is available online at http://www.ska.ac.za/.

Fig. 1. Pfaff-silberblau TQS 200 elevation worm gear screw jacks adjust antennas free from backlash

Fig. 2. TQS 200 linear direct drive from Columbus McKinnon Engineered Products

Fig. 3. Test procedure for proving the rigidity of TQS 200 at the Technical University of Munich

About Columbus McKinnon Engineered Products

The company Columbus McKinnon Engineered Products GmbH, Kissing/Germany, has ranked with its brand Pfaff-silberblau for many decades amongst the technology leaders in components and system solutions for mechanical motion and lifting technology. The portfolio ranges from sophisticated screw jack elements to innovative linear drives through to powerful lifting tables and wire rope winches. On the basis of these components, Columbus McKinnon Engineered Products also offers customized solutions for a wide range of different fields of application.

Columbus McKinnon Engineered Products is a subsidiary of the listed McKinnon Corporation (CMCO), Getzville/USA, a leading supplier of lifting and materials handling equipment.

Further information on Columbus McKinnon Engineered Products along with its brand Pfaff-silberblau is available online at www.pfaff-silberblau.com.

|

Company contact: COLUMBUS McKINNON Engineered Products GmbH Press: Petra Lugner E-mail: presse.kissing@cmco.eu Internet: www.pfaff-silberblau.com |

Visit our Landingpage

For 150 years we have been a technological leader in motion and lifting technology.

Whether turnkey lifting systems for trains and buses, spindle lifting elements, electromechanical components of linear drive technology or hoists

for steel and heavy industry, logistics, stage technology, offshore installations and ATEX areas.

Customers worldwide benefit from our products, services and complete solutions from project planning to maintenance.

Related Articles

Last year saw the start of a major construction project in Kazakhstan designed to establish the ferry terminal in Kuryk on the shores of the Caspian Sea as the hub for the transhipment-free transportation of goods to Europe. Columbus McKinnon Engineered Products, working closely with the local company in St. Petersburg/Russia, is now fitting this construction site out with two giant loading bridges each with 24 Pfaff-silberblau special screw jacks SHE 150.1 in addition to 48 special gear motors and, in doing so, is creating the technical basis that will allow entire freight trains to quickly drive in and out of the ferries before the end of the year.

In the summer of 2015, the region's first storm surge barrier will be inaugurated in Greifswald on the German Baltic Sea coast. Columbus McKinnon Engineered Products, Kissing, uses its PFAFF-silberblau SHE screw jacks to position the sliding gates of the harbour promenade to protect against flooding.

The “Iron Gate”, on the Danube River in the southern Carpathian Mountains on the border from Romania to Serbia, is regarded as one of the most impressive gorges in Europe. Two river power stations built in 1972 – “Iron Gate” 1 and 2 – with a lockage had tamed what had been up until then the most dangerous section of the Danube River for navigation. For the maintenance of this lockage, Columbus McKinnon Engineered Products GmbH, Kissing/Germany, has now designed and installed a special lifting device. The linear lifting solution consists of four high-precision and proven heavy-duty screw jack elements SHE 100.1 made by Pfaff-silberblau. These lift and lower the heavy lock gate weighing some 200 t by 700 mm – with a deviation of less than 0.1 mm.

For natural gas filter towers in the Saudi-Arabian desert, Columbus McKinnon Engineered Products GmbH, Kissing/Germany, has developed and installed a special lifting and traversing system for exchanging filter elements. This involves the use of 19 specially designed trolleys in three different sizes and eight gantry cranes made from ATEX-compliant lifting elements and electric wire rope winches from Pfaff-silberblau. This extremely heavy-duty special solution is capable of withstanding temperatures of up to 50 degrees Celsius, sand and dust and even the explosive environment.

Thanks to their robust design, the successful SHE screw jack elements from Pfaff-silberblau are perfectly equipped for use in difficult environmental conditions. Designed specifically for use in the extremely aggressive conditions of the paper industry, the company Columbus McKinnon Engineered Products GmbH (Kissing/Germany) has now extended its versatile SHE range with the option “stainless”. The newly developed SSP series from Pfaff-silberblau with integrally cast swivel brackets is easy to clean and satisfies with ease the exacting requirements with regard to corrosion protection in the paper making and processing industry.

Hardly any other workplace has such harsh environmental conditions as a steel mill. In the face of scorching heat and the greatest dirt, the heavy work is mainly carried out by machines – and for this they must also be designed to be particularly robust. Pfaff-silberblau Hebezeugfabrik GmbH, Kissing, has developed a special push tube construction based on the SHE 150 for the adjustment of casting trolleys for the continuous foundry of a large German steel manufacturer. This encapsulated system solution from the Kissinger drive technology specialist has passed its "acid test" in the foundry and is now also suitable for other applications in heavy industry in which high loads have to be moved under unfavorable environmental conditions.

Lifting heavy loads under the harshest of conditions has always been one of the specialties for the jacking systems from Pfaff-silberblau Hebezeuge GmbH, with headquarters in the Southern German town of Kissing. With a clever special jacking system based on its versatile SHE worm-gear screw jacks, the company is now reducing downtimes for the steel industry’s galvanizing lines. The crucial feature: A special sensor monitors the temperature of the gearbox oil, and an active cooling circuit keeps it at the ideal level. Simultaneously, a contactless sensor constantly monitors the temperature at the screw and does not turn off the system unless there is a risk of overheating. In this way, system operators can ensure that their systems remain functional, but also help to minimize operational interruptions.

Reliable and safe performance is essential also in lifting applications for outdoor use as well as in aggressive and hygienically critical environmental conditions. Columbus McKinnon Engineered Products GmbH, Kissing (Germany), has extended its versatile SHE series of the Pfaff-silberblau brand with a “stainless” option.

With its innovative new design and featuring fully rust-proof components, the SHE-S series meets exacting of requirements in terms of corrosion protection and cleanability with its corrosion-resistant design. Also thanks to its cost-effective construction, the SHE-S “stainless” series by Pfaff-silberblau is attracting more and more customers, particularly from the food processing industry, pharmaceutical industry, paper industry, petrol industry as well as from steel hydraulics construction.

Custom developed Pfaff-silberblau special lifting units for AGV from KUKA | Columbus McKinnon

AGV - ifting units for automotive industry

Columbus McKinnon Engineered Products is now supplying Pfaff-silberblau HEK10.1 lifting units as standard equipment to KUKA for integration into the KMP 1500 Mobile Platform. The lifting unit is a special development according to DIN EN 1494:2009-05 and EN 1570-1:2011+A1:2014 "Safety requirements for lifting tables" specifically for this automated guided vehicle, which moves around autonomously. With a lifting capacity of 10 kN per lifting unit, large loads can be moved around very flexibly on the small, manoeuvrable platform and moved vertically at speeds of 50 mm/s over a lifting path of 200 mm. Thanks to its two lifting units, the KMP 1500 transports loads weighing up to 1.5 tonnes safely through production and warehouses.

North America - EN

North America - EN