How to Choose Hoists and Cranes for Offshore Applications

Mining, Petroleum and Gas | Hoisting & Lifting | Crane Systems | By | Apr 15, 2014

Proper selection and specification of hoists, cranes and rigging hardware is always essential to safe overhead lifting, but in no environment is this more critical than on offshore oil and gas facilities.

In offshore oil and gas applications, there is a higher potential for flammable gases to be present. Therefore it is extremely important that proper safety precautions are taken to protect workers aboard these vessels and prevent equipment damage. It is important that the individuals responsible for specifying and purchasing material handling equipment for use in these environments can properly identify any hazardous locations or areas per the U.S. National Electric Code (NFPA 70), IEC Standard 60079, and other applicable local, national and international standards to ensure compliance with these regulations and safe operation. Additionally, the use of mechanically spark-resistant materials should be strongly considered, although these materials are not specifically addressed within many of the referenced standards.

In the absence of a definitive industry standard specifying what constitutes spark-resistant construction for hoists and cranes, it is frequently left to the knowledge and discretion of the seller to determine what materials will be used unless the purchaser designates specific requirements. If not clearly defined in the bid specification, the product and spark-resistant features provided often depend on the sourcing channels utilized by the end user.

Columbus McKinnon manufactures many products specifically designed for applications that require spark-resistant features. Our diverse, made in-America portfolio of hoists and trolleys are built to suit, rather than a mass produced “one size fits all” approach. Many of the products lend themselves to modification and substitution of materials that allows us to configure our hoists and trolleys to the specific application.

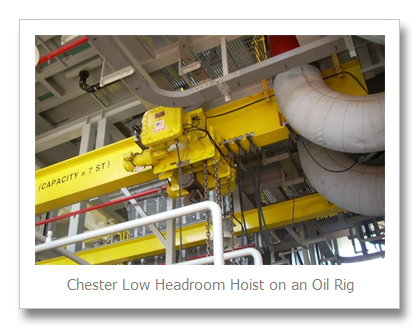

- Chester Hoist products utilize solid spark-resistant materials such as bronze hooks, trolley wheels and brake ratchets as well as stainless steel load chain, hand chain and hook latches. In some cases it is necessary to use nickel-diffused chains or copper-plated hooks due to headroom constraints or to reduce costs for equipment that will be used infrequently or in temporary applications. In these cases, Chester also can provide plated components to reduce costs. For equipment that is relied on heavily and is required to maintain spark and corrosion-resistant qualities for the life of the equipment, we actively promote the lasting protection of solid spark and corrosion-resistant materials rather than plated components.

- Yale Cable King wire rope hoists can be supplied in a wide range of capacities, lifting speeds and configurations with both spark and explosion resistance. The Cable King is available in a spark-resistant pneumatic model and an explosion-proof electric model, for Class 1, Division 1 or 2, Group C & D; and Class 2, Division 1 or 2, Group E, F & G.

- Yale Global King and Shaw-Box World Series wire rope hoists can also be specially configured for Class 1, Division 2, Groups B, C and D, with mechanical spark-resistant options.

Special consideration should also be given to the environmental conditions at the work site, including temperature extremes, humidity, corrosive atmospheres and the potential for dynamic loading due to vessel motion. Special materials, testing, material certifications and design modifications may be required to ensure safe operation and minimal down time of lifting equipment. Additional factors such as headroom clearance, end approach, frequency of use and the availability of utilities (electricity, compressed air) must also be considered.

Reading and understanding applicable safety standards and consulting with experienced and reputable manufacturers are two important steps in ensuring operator and facility safety when selecting hoists, cranes and rigging hardware for offshore applications.

Interested in learning more about Explosion Proof vs. Spark Resistant Hoists?

Check out our recent Safety Webinar.

Columbus McKinnon is a leading designer and manufacturer of hoists, cranes and rigging hardware for offshore environments. With a long history in the industry, we have years of experience working on offshore applications, their unique challenges and specifying the best products suited to harsh environments. Our Chester and Yale products have been used in these applications for decades and are relied on by end users around the world.

North America - EN

North America - EN