Hy-Thrust Actuators

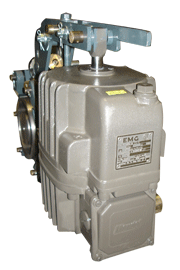

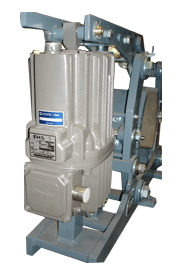

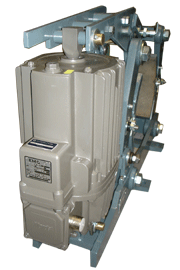

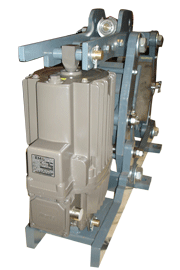

Magnetek actuators are electro-hydraulic devices which combine all the basic elements of a hydraulic system into one integral unit, consisting of an electric motor driving a hydraulic pump, piping, working cylinder and piston.

Features and Benefits

Features and Benefits

The function of the actuator is to convert electrical energy into a mechanical force hydraulically, producing a smooth straight line thrust, throughout the piston stroke. They are mainly used to release spring-set brakes like the MBT, MST and SDT.

THREE AVAILABLE ACTUATORS:

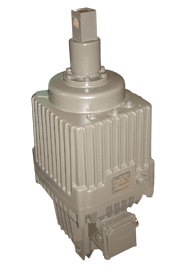

- AC three phase (Ed type)

- AC three phase explosion-proof (EdF type)

- DC (Eg type)

Magnetek offers the Ed type of 60 Hz actuator in 208VAC, 230/460VAC and 575VAC three phase versions. Other voltages from 110VAC to 690VAC, 50 Hz versions, explosion proof and DC (220VDC) actuators are available with longer lead times.

STANDARD FEATURES:

- Fast response - 2000 cycles per hour

- Long service life with minimum maintenance

- Extending forces from 50 lbs. to 900 lbs.

- Strokes from 2 to 7.8 inches

- Can be stalled at any stroke position without damage.

- Operating ambient temperature -25°C to +50°C with standard fluid (other ranges available on request)

- Class F insulation

- Aluminum housings

OPTIONS:

- Internal compression spring

- Externally adjustable, stepless time delays - both directions (S) (H)

- Vacuum poured stator windings

- Special paint for corrosion protection or easier decontamination

- Internal heaters for below -30 Deg. C ambient (110V or 220V)

- Explosion proof models available in VDE EEx d II and EEx d I

- Cast iron housings for nuclear applications

Options

ED23/5

The Ed23 actuator is the smallest in force and size and is the most commonly used. It produces 50 pounds of thrust on its extension stroke. Its total stroke is 1.97 inches. It can be supplied with an internal spring (Ed23/5C) so that when the power is turned off, it will retract. If used on a brake with an external spring, it is supplied without an internal spring (Ed23/5). The actuator consumes 165W, drawing 0.44A at 460VAC. It is normally used on shoe brakes from 5 inch to 10 inch wheel diameters.

ED30/5

The Ed30 actuator produces 67 pounds of thrust on its extension stroke. Its total stroke is 1.97 inches. It can be supplied with an internal spring (Ed30/5C) so that when the power is turned off, it will retract. If used on a brake with an external spring, it is supplied without an internal spring (Ed30/5). The actuator consumes 200W, drawing 0.38A at 460VAC. It is normally used on shoe brakes with 8 inch to 13 inch wheel diameters.

ED50/6

The Ed50 actuator produces 112 pounds of thrust on its extension stroke. Its total stroke is 2.36 inches. It can be supplied with an internal spring (Ed50/6C) so that when the power is turned off, it will retract. If used on a brake with an external spring, it is supplied without an internal spring (Ed50/6). The actuator consumes 260W, drawing 0.43A at 460VAC. It is normally used on shoe brakes with 13 inch to 16 inch wheel diameters.

ED80/6

The Ed80 actuator produces 180 pounds of thrust on its extension stroke. Its total stroke is 2.36 inches. It can be supplied with an internal spring (Ed80/6C) so that when the power is turned off, it will retract. If used on a brake with an external spring, it is supplied without an internal spring (Ed80/6). The actuator consumes 330W, drawing 1.1A at 460VAC. It is normally used on shoe brakes with 13 inch to 19 inch wheel diameters.

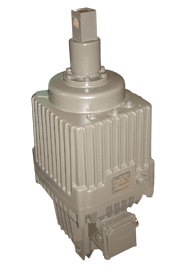

ED121/6

The Ed121, 201 and 301 are all the same physical size. Internal part changes give the user different available forces. The Ed121 actuator produces 280 pounds of thrust on its extension stroke. Its total stroke is 2.36 inches. It can be supplied with an internal spring (Ed121/6C) so that when the power is turned off, it will retract. If used on a brake with an external spring, it is supplied without an internal spring (Ed121/6). The actuator consumes 330W, drawing 1.1A at 460VAC. It is normally used on shoe brakes with 16 inch to 23 inch wheel diameters.

ED201/6

The Ed201 actuator produces 450 pounds of thrust on its extension stroke. Its total stroke is 2.36 inches. It can be supplied with an internal spring (Ed201/6C) so that when the power is turned off, it will retract. If used on a brake with an external spring, it is supplied without an internal spring (Ed201/6). The actuator consumes 450W, drawing 1.2A at 460VAC. It is normally used on shoe brakes with 19 inch to 23 inch wheel diameters.

ED301/6

The Ed301 actuator produces 675 pounds of thrust on its extension stroke and is the actuator with the largest force that is normally used. Its total stroke is 2.36 inches. It can be supplied with an internal spring (Ed301/6C) so that when the power is turned off, it will retract. If used on a brake with an external spring, it is supplied without an internal spring (Ed301/6). The actuator consumes 550W, drawing 1.3A at 460VAC. It is normally used on shoe brakes with 23 inch to 30 inch wheel diameters.

EMG Authorized Repair Center

Keep your ELDRO® and ELHY® brake thruster up and running at peak performance levels with Magnetek's Prefered Authorized repair services. Our technicians are factory trained to refurbish and repair your ELDRO and ELHY thrusters to ensure brake thrusters are operating safely and efficiently.

Quick-Ship Program

Magnetek Support Services

Over 150 years of combined experience means Magnetek has the expertise to skillfully serve your application needs before, during, and after we complete a project. With products designed to maximize the performance of your material handling system, start-up and field assistance, programs designed to train employees on optimal product usage, and quick, value-driven product repair and recertification, Magnetek is able to assist you with the highest level of service.

North America - EN

North America - EN