Pfaff-silberblau supplies PHOENIX telescopic lifting column for electron storage ring BESSY II

by | 07 Nov 2018

PHOENIX telescopic lifting columns from Columbus McKinnon Engineered Products can be used in a variety of applications, as illustrated by the current example of a special test bench application at the Helmholtz-Zentrum Berlin. Here, the Pfaff-silberblau lifting column PHOENIX takes over the manual height adjustment when guiding a photon beam to experimental stations (beamlines) – as sensitively as possible and backlash-free in order to guide the photon beam precisely through narrow apertures. The telescopic lifting column should therefore be as stiff as possible and the telescopic guide free of side play. Due to its technical design, Pfaff-silberblau's PHOENIX telescopic lifting column was able to meet the high demands of scientists in the standard version so well that no additional design effort was required for the height adjustment.

Exact height adjustment at the beamlines

At the Helmholtz-Zentrum Berlin für Materialien und Energie (HZB), scientists conduct research into complex material systems. They operate and use the photon source BESSY II – a synchrotron that delivers brilliant photon pulses. Experimental stations are connected to 48 beam holes. At one of these beamlines, researchers from the Max Planck Society investigate electrochemical processes in complex material systems under realistic conditions.

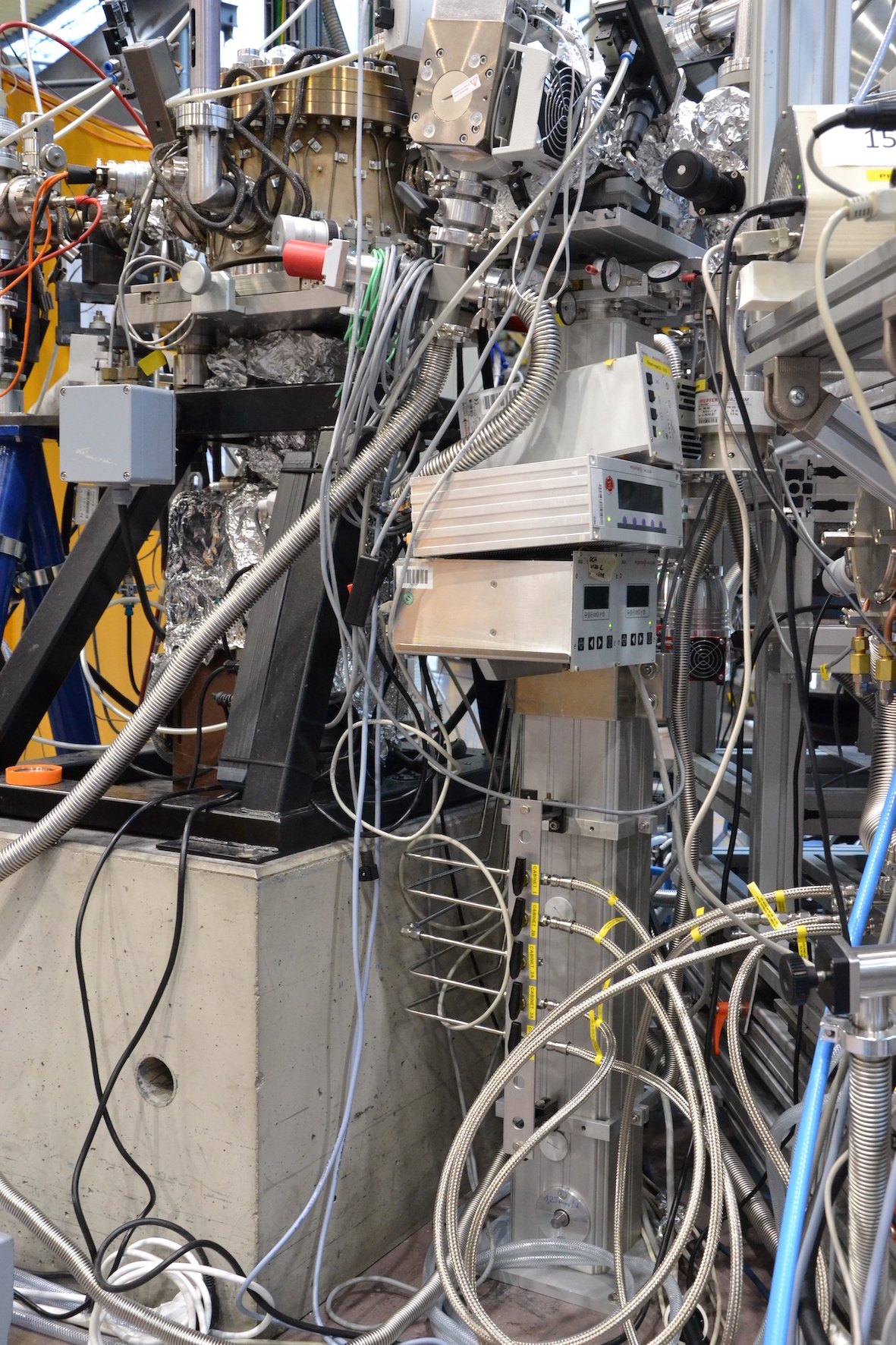

The experiments take place in a vacuum of 10-5 mbar. In the connected electron storage ring, on the other hand, there is an ultrahigh vacuum of 10-9 mbar. This is why a pumping stage with several chambers connected in series, which continuously sucks off gas with turbomolecular pumps, is necessary between the beam exit from a mirror chamber and the actual experiment. The individual chambers are connected to one another in such a way that the photon beam with a diameter of approximately 2 mm has to be precisely guided through apertures with diameters of 3 mm.

For this application, a lifting column was needed with a height of about 1200 mm, which can reliably support a weight force of at least 700 N and as such the pumping stage with the pumps and allow precision adjustment. It has to be adjustable in height by 500 mm in order to use it at other experimental stations with different beam heights.

The PHOENIX telescopic lifting column with manual drive and a lifting capacity of 1500 N has proven itself to be an ideal solution for this. The base plate of the telescopic lifting column is bolted directly to the floor of the experimental hall. The upper head plate of the PHOENIX lifting column has been removed and replaced with an adjustment unit that allows pivoting and alignment of the attached pumping stage in four degrees of freedom with an accuracy of up to 0.05 mm. The closed outer housing made of robust aluminium profile tubes makes the PHOENIX lifting columns from Pfaff-silberblau insensitive to dirt and thus also low maintenance.

The solution was set up within a week and aligned with a theodolite exactly to the photon beam. The pumping stage has been operating trouble-freely for about six months, without any readjustment being necessary to date.

Multi-lifting systems also possible

PHOENIX telescopic lifting columns from Pfaff-silberblau can also be combined into multi-lifting systems. The precision of the lifting process, the admissible off-centre load pick-up and its versatility in the way it is installed – vertically, horizontally or headfirst – qualify these lifting columns for a wide range of tasks. As such, they are also used in height-adjustable work stations, e.g. in engine assembly in automotive production, for the positioning of components in stop-and-go mode of production lines and for lifting large and heavy components with variable geometry, e.g. in wing assembly in aircraft construction.

For more information on the PHOENIX telescopic lifting column from Columbus McKinnon, please visit www.pfaff-silberblau.com/lifting-columns/.

Figures 1 and 2: PHOENIX telescopic lifting columns from Pfaff-silberblau

Fig. 3: Round mirror chamber and consoles clamped to the PHOENIX telescopic lifting column for holding power supplies and control units of connected pumps (Photo credits: Helmholtz-Zentrum Berlin)

About Pfaff-silberblau and Columbus McKinnon Engineered Products

The company Columbus McKinnon Engineered Products GmbH, Kissing/Germany, has ranked with its brand Pfaff-silberblau for many decades amongst the technology leaders in components and system solutions for mechanical motion and lifting technology. The portfolio ranges from sophisticated screw jack elements to innovative linear drives through to powerful lifting tables and wire rope winches. On the basis of these components, Columbus McKinnon Engineered Products also offers customized solutions for a wide range of different fields of application.

Columbus McKinnon Engineered Products is a subsidiary of the listed McKinnon Corporation (CMCO), Getzville/USA, a leading supplier of lifting and materials handling equipment. Columbus McKinnon Engineered Products is a partner of the VDMA sustainability initiative Blue Competence (www.bluecompetence.net).

Further information on Columbus McKinnon Engineered Products along with its brand Pfaff-silberblau is available online at www.pfaff-silberblau.com.

Company contact: COLUMBUS McKINNON Engineered Products GmbH Press: Petra Lugner E-mail: presse.kissing@cmco.eu Internet: www.pfaff-silberblau.com |

Visit our Landingpage

For 150 years we have been a technological leader in motion and lifting technology.

Whether turnkey lifting systems for trains and buses, spindle lifting elements, electromechanical components of linear drive technology or hoists

for steel and heavy industry, logistics, stage technology, offshore installations and ATEX areas.

Customers worldwide benefit from our products, services and complete solutions from project planning to maintenance.

United Kingdom - EN

United Kingdom - EN