Conveyance Solutions

Industrial conveyors are a fundamental component of modern manufacturing and production systems. These machines are used to move raw materials, components, and finished products throughout a factory or production facility. By automating the transport of goods, conveyors improve efficiency, reduce labor costs, and enhance overall productivity. Various conveyor types are available, each with a unique design and application. Some common examples include belt conveyors, roller conveyors, pallet conveyors, and flexible chain conveyors. Understanding the different types of conveyors and their specific uses can help businesses optimize their operations and maximize their production capabilities.

Contact Our Conveyance Division To Discuss Your Application Needs

Types of Industrial Conveyor Systems

Fabric belt conveyors are some of the most common conveyor types in various industries such as manufacturing, agriculture, and food production. One of the key benefits of these conveyor types is their ability to operate continuously, making them ideal for high-volume operations handling large quantities of goods. Additionally, they offer a smooth and consistent transport surface, which minimizes the risk of damage to goods and ensures safe and efficient movement from one location to another. Overall, fabric belt conveyors are reliable, efficient, and versatile options for material handling operations in almost any industry.

Flexible chain conveyors are used in various industries to transport products and materials along a production line. They are designed to efficiently handle a wide range of products, from small parts to packaged foods and totes. Flexible chain conveyors are highly versatile due to their ability to bend and flex, allowing them to navigate obstacles and fit into tight spaces while maintaining high accuracy and control. They can be configured with numerous chain types and customized with additional accessories and modules to fit the needs of almost any production line. They can also handle products with varying shapes and sizes, making them a versatile choice for manufacturers in various industries.

Pallet systems conveyors are commonly used in manufacturing, automated assembly, and warehousing applications for transporting products on pallets. These conveyors are designed to handle various product sizes from large appliances to small electrical components. Mounting products on pallets for manual or automated assembly ensures they are positioned correctly throughout the manufacturing line to better interface with robots and human operators. This method of conveyance is also ideal for delicate products that require smooth movement and buffering space, as well as cleanroom production environments. Pallet systems conveyors are modular in design, allowing for easy customization and adaptation to changing production needs.

Sanitary and stainless-steel conveyors are used in industries that require high cleanliness levels, such as food and beverage, pharmaceuticals, and personal care products. These conveyors are made of stainless steel and are designed with minimal ledges and flat surfaces, making them easy to clean and sanitize. They are also designed with food-grade belts and plastic components, reducing the risk of contamination. Sanitary and stainless-steel conveyors are often equipped with specialized features such as water-resistant bearings, self-cleaning mechanisms, and quick-release belts, making them the ideal choice for manufacturers prioritizing cleanliness and safety.

Accumulation conveyors are essential in many production and manufacturing facilities, allowing for buffering and accumulating products between different stages of the production process. Accumulators are available in a range of sizes, from small accumulation tables for product orientation and flow control to expansive conveyor loops for large-scale accumulation and buffering. Unlike other conveyor types, accumulation systems enable the continuous flow of products while preventing collisions and ensuring that products are correctly oriented for downstream processes. By creating a controlled queue of products, accumulation conveyors also allow operators to manage workflow interruptions or temporary equipment stoppages, reducing the risk of downtime and maximizing production efficiency.

What materials are used in conveyors?

Metals

Steel and aluminum are often used in conveyor systems due to their durability and strength. These materials can withstand heavy loads and harsh environments, making them ideal for applications in industries such as metal working, manufacturing, and food production.

Plastics

Polyethylene, polypropylene, and PVC are commonly used in conveyor systems due to their lightweight and versatile properties. These materials can be molded into various shapes and sizes, making them ideal for food processing and packaging applications.

Rubber

Rubber is a flexible and durable material often used in conveyor belts and rollers. It can withstand high temperatures, abrasive materials, and heavy loads, making it ideal for applications in industries such as mining, agriculture, and construction.

Fabrics

Polyester and nylon are often used in fabric and belt conveyors. These lightweight and flexible materials make them ideal for food processing and logistics applications.

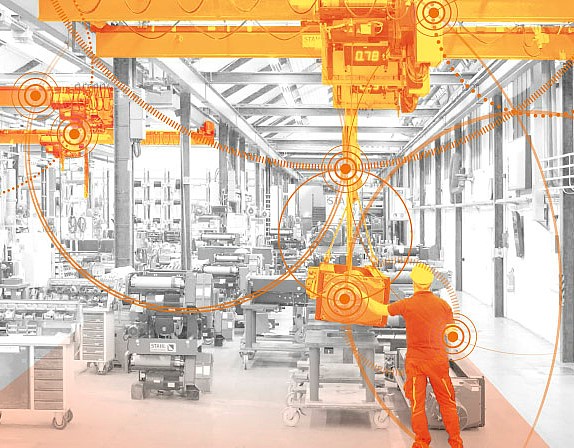

Explore Our Intelligent Motion Solutions

Every Columbus McKinnon product is engineered to help our customers work smarter, while improving the safety, uptime, and productivity of their operations. Our innovative, intelligent solutions combine equipment used to lift and move materials with industry-leading control and automation technology.

Featured Industries

The automotive industry relies heavily on conveyance solutions to efficiently move materials and products through their manufacturing processes. Conveyors move components, parts, and finished products throughout the production line, from assembly to painting to final inspection. They can handle heavy loads and move materials at high speeds, making them ideal for mass production. These systems are customized to meet the specific needs of the automotive sector, from handling delicate components to managing complex assembly lines.

The food industry relies heavily on conveyance solutions to ensure safe, hygienic, and efficient production processes. Conveyors are used to move raw materials, ingredients, and finished products throughout the production line, from mixing and processing to packaging and storage. They are designed to handle food-grade materials and meet strict hygienic standards, ensuring the products remain free from contamination. These systems are customized to meet the industry’s specific needs, including managing delicate and fragile products, handling high-speed operations, and complying with food safety regulations for different food products from packaged baked goods to raw meat and dairy.

The pharmaceutical industry relies heavily on conveyance solutions to ensure the safe and efficient production of medicines and medical supplies. These conveyors are designed to meet stringent hygienic and safety standards, ensuring the products remain free from contamination and are handled in a controlled environment. These systems can handle delicate and fragile products, integrate with other pharmaceutical equipment, and comply with industry regulations, ensuring that the products are of the highest quality.

In the beverage industry, bottle conveyor systems are an essential part of most bottling lines. This ever-growing industry is placing increasing pressure on manufacturers to maintain high productivity levels by minimizing downtime and increasing throughput. At Columbus McKinnon, we understand the importance of efficient and streamlined production processes, which is why we offer a range of solutions to help you achieve your goals.

North America - EN

North America - EN