Applications - Industries - Solutions - Systems - Meet the Team

Crane Automation Increases Safety, Uptime & Productivity

Our automated crane systems are designed to improve safety, uptime and productivity in your facility. Not only does automation technology allow you to build safety right into equipment with no-fly zones and off-center pick prevention, it also provides you with real-time data and information that enables you to improve operational efficiency and make smarter decisions, faster. Access to real-time data through crane automation systems allows you to better:

- Plan for maintenance

- Predict equipment failures

- Identify needs for operator training

- View and monitor single or multiple pieces of equipment within a facility

Browse through our Intelli-Crane™ family of automated crane systems to learn more. With decades of experience in crane automation, we're here to provide you with the expertise to get your system up and running. Reach out to us to learn more about the impact crane automation can have in your facility.

Automated Crane Industries & Applications

We are experienced. For more than 20 years, we have provided customers with technology solutions and components for automated crane systems. Our automation division understands the challenges and benefits of utilizing automation in applications throughout many industries, ranging from automotive and metals production to power generation and construction. Here are a few examples of where our automated crane systems have been used.

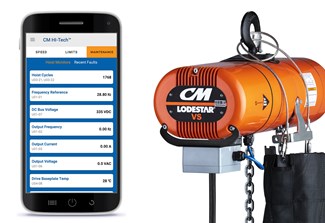

- Crane monitoring and diagnostic reporting

Our Intelli-Connect™ diagnostics and analytics technology enables quick and easy programming, maintenance, monitoring, and troubleshooting of overhead cranes and hoists right from your smartphone. With diagnostic information available at your fingertips, you can address issues more quickly, plan maintenance, and ultimately reduce downtime.

- Auto-dispatch

In the automotive industry, we've assisted in creating an automated electro-static painting system consisting of four identical dipping cranes working congruently over one tank line. We've also assisted in dip tank treatment in the steel industry. Automating dip tank treatment is a great way to increase safety by removing workers from the vicinity of hazardous chemicals or high voltage used in electro-static painting on automotive assembly lines. Intelli-Guide is an excellent option for your next auto-dispatch application.

VIEW INTELLI-GUIDE

- Storage and retrieval

From steel coils and automotive dies to lumber and boat storage and retrieval systems, we've handled them all. Our automated systems are proven to increase storage space and efficiency in a variety of applications.

- Line speed matching

This important feature ensures that multiple hoists lift and traverse one item while moving in tandem with a piece of equipment on the ground (eg. conveyor). This allows a single operator to mate two items on an assembly line safely and more efficiently.

- Crane-to-crane synchronization

When two or more cranes are required to move a single load, our technology can synchronize the motions of multiple cranes with the use of a single remote control. Using this technology with drive synchronization software also helps assure safe movement to minimize the risk of damage to crane equipment as well as the product being moved.

- Monorail positioning

We designed and installed a customized overhead material delivery system that automated and integrated nine overhead monorail carriers from two separate wheel and strut delivery lines through a single, shared paint line process for the U.S. Air Force. We did this using Magnetek's IMPULSE® drives and conductor bar systems.

- Multi-level collision avoidance

In marine applications, like a shipyard, our multi-level collision avoidance systems can help eliminate accidents when several overhead crane systems are running at once.

- Crane-to-ground based equipment interaction

When there are machine tools or robotic arms operating on the ground that can interfere with the path of an overhead crane, we can develop a variable no fly zone. This enables the floor device and crane to communicate, eliminating the chance for collision.

- No-fly zones

This technology is used to designate areas where a crane should slow down or stop to prevent suspended loads from injuring an operator or colliding with equipment. Be sure to consider Intelli-Protect for your next no-fly zone application.

- Off-center pick detection

Swinging loads, whether caused by misalignment or snags, are not only dangerous for your employees but can damage equipment, resulting in costly repairs and downtime. Our off-center pick detection technology detects a load misalignment or snag condition and alerts operators with a visible and audible warning. Intelli-Lift is the perfect match for off-center pick detection.

Industries

Engineered-to-Order Solutions

From power generation and food handling to aerospace and steel making, our automation team is well-versed in building the right automated crane solution to meet your needs. Take the first step to increasing the safety, uptime and productivity in your facility by having a conversation with our experienced automation team members. We'll discuss your goals, timelines, specs and more to help design the right automated system for you.

START A CONVERSATION WITH OUR AUTOMATION DIVISION

Featured Crane Automation Systems

Intelli-Connect wirelessly delivers diagnostic and analytic information from Magnetek VFDs to reduce downtime, accelerate commissioning and enable predictive maintenance.

Intelli-Connect enables you to:

- Access the latest user manuals and troubleshooting guides

- Adjust parameters and store backup sets to the wireless operator or PED

- Access technical support

Protect personnel and improve facility throughput with our Intelli-Protect No-Fly Zone Technology.

Intelli-Protect allows you to:

- Configure to exact requirements

- Optimize productivity

- Ensure predictable, repeatable operation

- Improve facility safety

- Get flexibility for your application needs

Intelli-Guide Auto-Dispatch Technology can help streamline your operations and improve efficiency as compared to processes that are manually operated.

Intelli-Guide can help you:

- Maximize productivity and efficiency

- Increase uptime

- Improve facility and operator safety

- Streamline operations and increase material flow

Intelli-Lift Side Pull and Off-Center Pick Technology detects a load misalignment or snag condition and alerts operators with a visible and audible warning before a dangerous situation occurs.

Intelli-Lift provides:

- Easy-to-access system data

- Precision load control

- Reduced stress on equipment

- Quick, easy installation

Meet the Team

Rick Emmer

Rick Emmer is a Business Development Manager for Columbus McKinnon's Automation Division. Rick has over 25 years of experience and a deep understanding of how to deliver the right automation solution to best meet customers' application needs in the conveyor and palletizing industries. Rick holds a BS Degree in Business with a Major in Marketing from the University of Wisconsin - Milwaukee.

Pat Buehler

Pat Buehler is a Senior Automation Specialist for Columbus McKinnon's Automation Division. With more than 30 years of direct experience in crane and motor control industries, Pat brings a demonstrated history of working in the electrical and electronic manufacturing industry and is skilled in process control, control system design, SCADA and electrical wiring.

Jean-Luc Kunicki

Jean-Luc is a Systems Applications Sales Engineer in Columbus McKinnon's Automation Division. Jean-Luc graduated from Milwaukee School of Engineering in 2008 with a Bachelor of Science in Electrical Engineering.

Mike Hermans

Mike Hermans is a Sales Engineer for Columbus McKinnon's Automation Division. Mike is a graduate of the Milwaukee School of Engineering and Lübeck University of Applied Sciences. He holds two B.S.E.E Degrees.

START A CONVERSATION WITH OUR AUTOMATION DIVISION

North America - EN

North America - EN