Benefits of VFD Control vs. 2-Speed Control for Cranes and Hoists

Power & Motion Technology | Automation | By Casey Cummins | May 13, 2021

When comparing variable frequency drives (VFD) to 2-speed control for use in cranes and hoists, there are a variety of factors you should take into consideration. These range from load control and speed adjustment to efficiency and extended hoist life. In this blog, we will compare the two to show you the benefits of VFD crane control over 2-speed.

GREATER SPEED ADJUSTMENT

- VFD: Lets you to choose from multiple speeds, allowing for customization of the controls to your application.

- 2-Speed: Locked into 2-speeds depending on what is provided by the motor manufacturer. This cannot be adjusted.

IMPROVED LOAD CONTROL

- VFD: Ensures smooth operation by gradually slowing down a load. VFD crane control also allows for smooth acceleration to minimize load swings in the traverse motions.

- 2-Speed: When the operator is locked into two speeds, it can be difficult to precisely position a load. Speed control is very limited, which has the consequence of shock loading and load swing. Jogging the hoist to position the load causes a high inrush to the motor that can lead to increased heating and a lower lifespan for the hoist.

BRAKES

- VFD: Slow down the crane electronically via dynamic braking. The motor regenerates braking energy back to the controls, which can be simply dissipated as heat through resistors or recycled back to the power source. The brake is only used for parking or emergency stops, which dramatically extends brake life.

- 2-Speed: Brakes are used to slow down the hoist. This causes continuous wear and tear, increased maintenance, and more frequent brake replacement. Sudden and uncontrolled braking can cause excessive load sway.

EFFICIENCY

- VFD: Only consumes the power that's needed by the motor load, thus saving energy compared to contactors and soft starters.

- 2-Speed: Speed resistors dictate the energy consumed, and the control system is constantly wasting this energy. Starts are harsh and commonly pull five to eight times the normal full load current rating of the motor.

INCREASED HOIST LIFE

- VFD: Some VFDs provide thermal overload and overcurrent protection for the hoist motor, prolonging its life. The motor is soft started by the VFD, which extends the life of the insulation and windings. VFDs also utilize a ramp-to-stop method of braking rather than using brake shoes to slow down. This minimizes the forces seen by the crane structure. The brake is only used for parking and emergency situations, which extends brake life.

- 2-Speed: Increased maintenance on the brakes and cleaning of speed resistors. The motor will have a shorter life due to high inrush currents.

REGENERATIVE ENERGY

- VFD: Deceleration and lowering of a hoist results in regenerative energy produced by the motor. This energy can be transformed into heat using a braking resistor or it can be conditioned and sent back to the source, thus netting energy savings. An AC regenerative controller will redistribute that energy, which would otherwise be wasted when converted to heat with a braking resistor.

- 2-Speed: Regenerative energy is dissipated through speed resistors or by the brake shoes. All energy is converted to heat and lost.

DIGITAL DIAGNOSTICS

- VFD: Digital diagnostics aid in maintenance and troubleshooting on the machine or remotely.

- 2-Speed: Provides no ability to monitor or record diagnostic information.

VFD control provides many benefits as compared to 2-speed control in your crane or hoist. By using VFD control throughout your facility, you not only prolong the life of your equipment and save money on energy costs, but you can standardize the type of motor used on equipment for a lower total cost of ownership.

Training Courses on Crane Drives

Whether you need training on crane operation, installation or maintenance, we have a course for you. We offer a wide variety of courses ranging from overhead crane and hoist inspection certification to mobile crane operator training applicable to professionals in almost any industry. We even offer a NCCCO Certification prep course for individuals interested in NCCCO Overhead Crane Operator Certification.

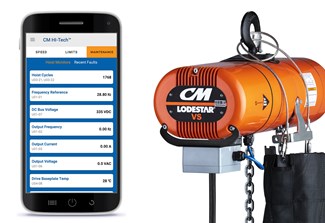

Lodestar VS with Intelli-Connect

The CM Lodestar VS is now available with Intelli-Connect™ Diagnostics and Analytics technology. Intelli-Connect enables quick and easy programming, maintenance, monitoring, and troubleshooting of the Lodestar – all from a tablet or smartphone.

How does it work? Using the Intelli-Connect Mobile and Mobile+ apps, you can

wirelessly access detailed information right from the plant floor, without the need to attach a programming cable. Intelli-Connect is available as an option on all new Lodestar VS units or in a retrofit kit for units already in service.

Related Articles

When choosing a variable frequency drive (VFD) for your crane or hoist application, we recommend using a crane-specific VFD and not a general purpose VFD. Why? Using a crane-specific VFD can have a significant impact on the safety, uptime, and productivity of your crane application, and can get you up and running quicker and easier.

North America - EN

North America - EN